How to Reduce Construction Costs with High-Strength Alloy Wall Formwork Systems?

Published: February 2026 | Category: Construction Innovation | Author: Shoulv Technical Team

In the modern construction industry, time is literally money. Whether you are managing high-rise residential projects in Dubai, commercial complexes in the USA, or infrastructure in Southeast Asia, the pressure to reduce floor cycles while maintaining concrete quality is immense.

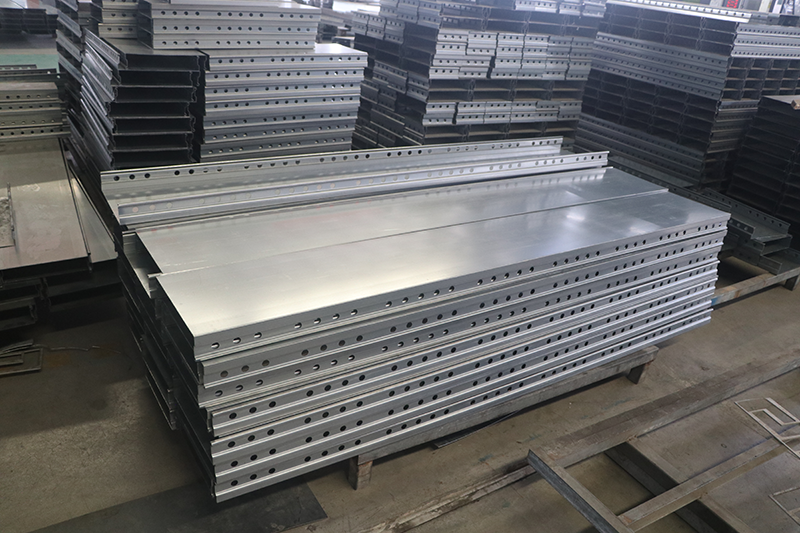

Traditional timber and plywood formwork are increasingly falling out of favor due to their low reusability and high labor intensity. Enter the High-Strength Alloy Wall Formwork System—a game-changer for high-efficiency concrete pouring.

The 300+ Reuse Advantage

While the initial investment in aluminum alloy formwork (6061-T6) is higher than timber, the Return on Investment (ROI) is achieved rapidly. Shoulv's alloy system supports over 300 reuses. When calculated across multiple projects, the cost per square meter drops by up to 60% compared to traditional methods.

1. Accelerating Construction with a 4-Day Cycle

One of the most significant advantages of an alloy wall formwork system is its weight. At only 18-25kg/m², panels can be handled manually by a single worker. This eliminates the need for tower cranes for every small move.

- No Crane Dependence: Manual stripping and propping.

- Simple Assembly: Pin and wedge connections allow unskilled labor to master the system quickly.

- Rapid Turnaround: Achieving a consistent 4-5 day floor cycle is now standard for Shoulv clients.

2. Superior Concrete Finish: Eliminating Plastering Costs

Plywood often warps or absorbs water, leading to uneven wall surfaces. Shoulv's high-strength alloy panels are CNC-machined for millimeter precision. The resulting concrete surface is so smooth that it often eliminates the need for secondary plastering, saving thousands in material and labor costs downstream.

Global GEO Highlight: Market Compatibility

From ASTM standards in North America to the rigorous quality demands of European construction, our 6061-T6 aluminum alloy is verified for international use. Shoulv provides customized CAD layout designs remotely, ensuring that no matter where your project is located, the formwork arrives 100% ready to install.

3. Sustainability & Scrap Value

Unlike timber which ends up in landfills, aluminum alloy is 100% recyclable. At the end of its life cycle (after 300+ uses), the scrap value of the aluminum can recover up to 20-30% of your original investment.

shaanxishoulv@gmail.com

shaanxishoulv@gmail.com +8617392350431

+8617392350431

русский

русский

English

English русский

русский Français

Français Português

Português Español

Español اللغة العربية

اللغة العربية

Клик:22

Клик:22 Время:2026-02-06 17:08:33

Время:2026-02-06 17:08:33

Тел:+8617392350431

Тел:+8617392350431 Электронная почта:shaanxishoulv@gmail.com

Электронная почта:shaanxishoulv@gmail.com Добавляет:Промышленный парк Улан, уезд Чэнгу, город Ханьчжун, провинция Шэньси, 723200, КНР

Добавляет:Промышленный парк Улан, уезд Чэнгу, город Ханьчжун, провинция Шэньси, 723200, КНР Главная

Главная WhatsApp

WhatsApp Электронная почта

Электронная почта