-

Optimizing Shopping Mall Construction with Modern Formwork Systems

The construction of large-scale shopping malls presents unique challenges, including vast floor plates, complex architectural features, and immense pressure to open for business. Modern aluminum formwork systems are engineered to optimize this process, delivering the speed, quality, and economic efficiency required for successful retail development.

456

456 2025-10-11

2025-10-11

-

Using Advanced Formwork Systems in Hotel and Hospitality Construction

The hotel and hospitality sector demands rapid construction, high-quality finishes, and robust structures to meet tight opening deadlines and ensure long-term guest satisfaction. Advanced aluminum formwork systems are uniquely suited to deliver on these critical requirements, making them the preferred choice for modern hotel developers and contractors.

444

444 2025-10-11

2025-10-11

-

Efficient Formwork Solutions for Educational Facility Construction

The construction of schools, universities, and other educational facilities requires a careful balance of speed, budget, and quality. Efficient formwork solutions are key to meeting tight project timelines, often constrained by academic calendars, while ensuring the creation of durable, functional learning environments. Modern aluminum formwork systems are specifically engineered to meet these unique demands.

425

425 2025-10-11

2025-10-11

-

Special Formwork Considerations for Hospital and Healthcare Construction

Hospital construction presents unique challenges that demand specialized formwork solutions. Beyond structural integrity, healthcare facilities require precision, hygiene, and flexibility to accommodate complex layouts and stringent regulatory standards. Understanding these specialized needs is crucial for successful project delivery.

431

431 2025-10-11

2025-10-11

-

Applications of Alloy Formwork in Large-Scale Infrastructure Projects

Large-scale infrastructure projects demand construction solutions that deliver durability, efficiency, and precision on a massive scale. High-strength alloy formwork systems have become the preferred choice for such projects, offering the robustness and versatility needed to build the foundations of modern society.

468

468 2025-10-11

2025-10-11

-

Specialized Formwork Solutions for Industrial Facility Construction

Industrial construction—from manufacturing plants and warehouses to power facilities—presents unique challenges that demand robust, adaptable, and efficient formwork solutions. Unlike standard building projects, industrial facilities require specialized systems capable of handling massive loads, complex geometries, and demanding construction schedules.

484

484 2025-10-11

2025-10-11

-

Using High-Strength Formwork in Commercial Building Construction

Commercial construction projects—from skyscrapers to shopping malls—demand robust solutions that can withstand high concrete pressures, rapid cycle times, and repetitive use. High-strength aluminum formwork systems are engineered specifically to meet these rigorous demands, offering unparalleled performance for large-scale commercial developments.

501

501 2025-10-11

2025-10-11

-

Optimizing Residential Building Construction with Aluminum Formwork

In the fast-paced world of residential construction, efficiency, quality, and cost-effectiveness are paramount. Aluminum formwork systems have emerged as a superior solution for developers and contractors aiming to optimize the entire building process for apartments, condominiums, and housing complexes.

500

500 2025-10-10

2025-10-10

-

Continuous Performance Monitoring Services for Formwork Systems

In modern construction, data-driven insights are key to maximizing efficiency and mitigating risk. Moving beyond reactive fixes, Shoulv Alu Formwork offers continuous performance monitoring services that provide real-time oversight of your formwork system throughout the construction cycle, transforming on-site execution into a optimized, predictable process.

474

474 2025-10-09

2025-10-09

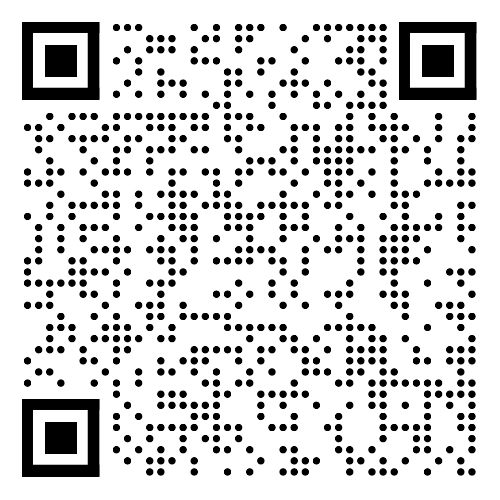

shaanxishoulv@gmail.com

shaanxishoulv@gmail.com +8617392350431

+8617392350431

English

English

English

English русский

русский Français

Français Português

Português Español

Español اللغة العربية

اللغة العربية

Tel:+8617392350431

Tel:+8617392350431 Email:shaanxishoulv@gmail.com

Email:shaanxishoulv@gmail.com Adds:Wulang Industrial Park, Chenggu County, Hanzhong City, Shaanxi Province, 723200, P.R. China

Adds:Wulang Industrial Park, Chenggu County, Hanzhong City, Shaanxi Province, 723200, P.R. China Home

Home WhatsApp

WhatsApp Email

Email